Acrylic Cutting And Engraving

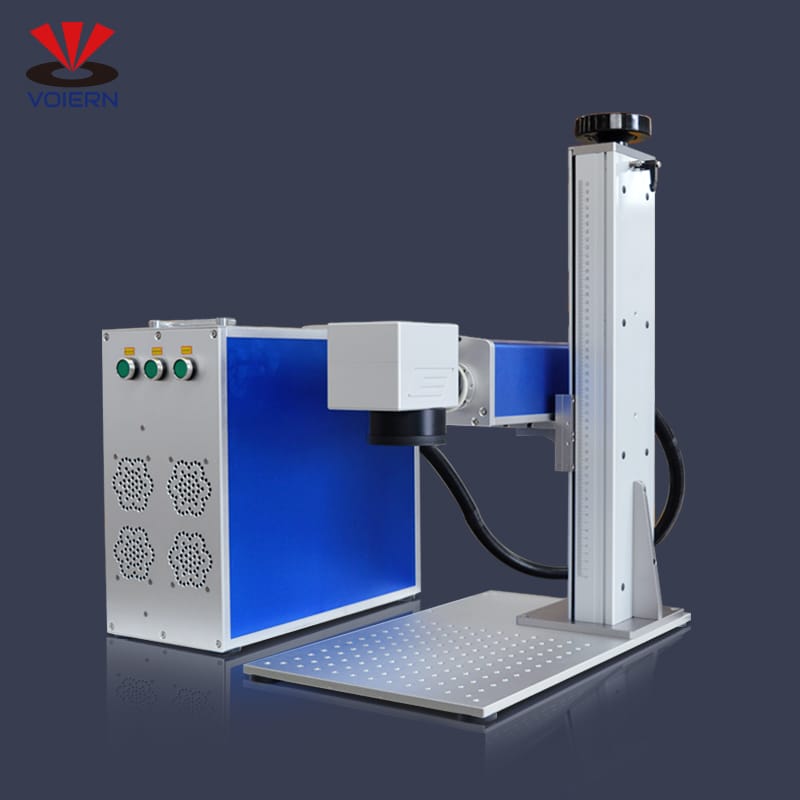

Laser engraving and cutting machines

applied on acrylic

Laser cutting is a contact-free cutting method. The laser can cut a variety of patterns, words, etc. The technology uses the energy released by the laser beam to the acrylic surface to melt the acrylic sheet, and the laser cutting method can be used for precise cutting. Complex shaped materials.

Acrylic sheets are mainly used for engraving, decoration, handicraft production, and extrusion type, which are usually used for advertising signs, light boxes, etc. PMMA has the advantages of light weight, low cost and easy molding. Its molding methods include casting, injection molding,machining, and thermoforming. In particular, injection molding can be mass-produced, with simple process and low cost. Therefore, its application has become increasingly widespread, and it is widely used in instrumentation parts, automobile lamps, optical lenses, transparent pipes, and the like.

Acrylic cutting is used in construction applications. Plexiglass is mainly used in lighting, roofing, roofing, stairs and interior wall panels. In recent years, plexiglass has also been used quite rapidly in lighting shades and automotive lighting for highways and high-end roads. With the construction of large city hotels, hotels and high-end residential buildings, the light-emitting body has developed rapidly. The light-emitting body made of plexiglass extrusion plate has the characteristics of high overall structural strength, light weight, high light transmittance and good safety performance. Compared with inorganic glass lighting devices, it has great advantages.In terms of sanitary ware, plexiglass can be used to make bathtubs, washbasins, dressing tables and other products. The plexiglass bathtub has been widely used in recent years due to its luxurious appearance, deep feeling, easy cleaning, high strength, light weight and comfortable use. Acrylic is the best new material that can be used to make sanitary ware after ceramics. Compared with traditional ceramic materials, acrylic has the following advantages in addition to unparalleled high brightness: good toughness and not easy to break; strong repairability, just use a soft foam to remove the toothpaste to wipe the sanitary ware; soft texture, winter There is no sense of cold and biting; the color is bright, which can satisfy the individual pursuit of different tastes. Acrylic basins, bathtubs and toilets are made of acrylic, which are not only beautiful in style, durable, but also environmentally friendly. Their radiation levels are similar to those of the human body.

Acrylic laser cutting is used in a variety of fashion boutiques, such as leather bags, waist, watches, high heels, heels, hair accessories, brooches, bracelets, buttons, earrings, necklaces, rings, charms, photo frames, Wenzhen, etc. There is a lot of space for unlimited development. Because acrylic materials have high plasticity and good surface hardness and transparent luster, they are often used by designers to match various materials in various delicate container designs, adding container texture and practicality, such as lipstick and Exquisite containers such as chemicals, such as massagers, jewelry boxes, fans and other daily necessities.