knowledge

Published by: Voiern

Voiern August 23,2019

August 23,2019

Voiern

Voiern August 23,2019

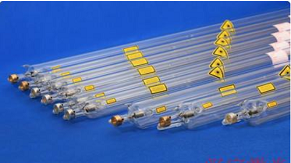

August 23,2019 How to use a laser engraver in winter

In winter, when the ...

Vistor

66

66

Published by: Voiern

Voiern August 06,2019

August 06,2019

Voiern

Voiern August 06,2019

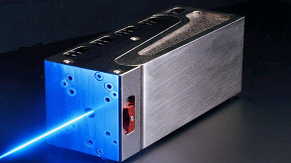

August 06,2019 Flexible Application of Laser Marking Technology in Electronic Industry

Laser marking machin...

Vistor

66

66

Published by: Voiern

Voiern August 25,2019

August 25,2019

Voiern

Voiern August 25,2019

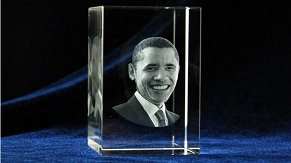

August 25,2019 How to choose best laser marking machine

The UV laser marking...

Vistor

66

66

Published by: Voiern

Voiern August 26,2019

August 26,2019

Voiern

Voiern August 26,2019

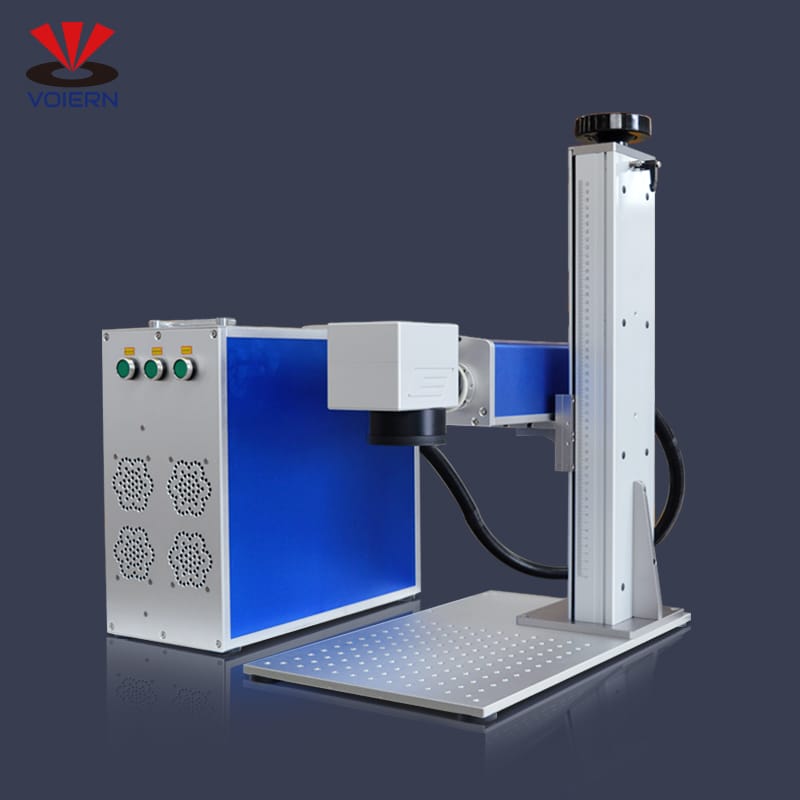

August 26,2019 How to buy laser engraving machine

There are too many p...

Vistor

66

66